Data Sheet

SORinc.com

Basic Bottle Sampling Systems

Models:

BBSS

Warranty:

(opens in a new tab)

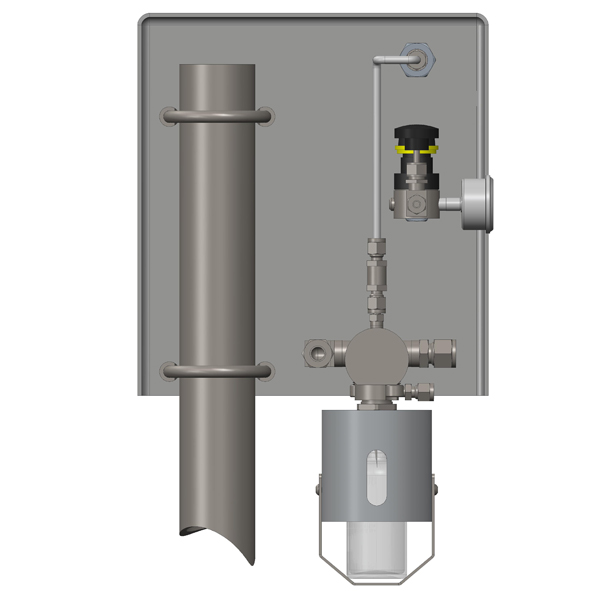

(opens in a new tab)The SENSOR Basic Bottle Sampling System (BBSS) is a closed-loop liquid grab sample system ideal for processes with pressure less than 150 psig and process temperature less than 135ºF. The sample is dispensed into the sample bottle by merely turning a valve. Process pressure forces the sample through the valve into the bottle. With the SENSOR Needle Evacuation System (NES), zero dead volume is ensured throughout the sample valve assembly by forcing out any vapor-locked liquid.

- Simple, flow-thru valve design ideal for fast loop

- Zero dead volume

- Replaceable process and vent needles

- Available with SENSOR Needle Evacuation System for residual elimination and zero emission

- Zero emissions/captured vent

- Highly customizable based on process conditions and operator requirements

- Primary Flow-Thru Sample Valve features a side-ported needle valve with packing below the threads; ensuring that the stem will not seize due to process build-up

- Side-ported Vent Needle prevents plugging of the vent port

- 316L standard material; other materials available

- Replaceable Process and Vent Needles

- Non-metallic bottle shroud protects operator in case of a shattered bottle

- Operation and Installation Manual for each system

Be sure and look at the other sampling system models that are available like the Cylinder Sampling Systems(opens in a new tab).

General Instructions

Product Bulletins

Other

- SENSOR Bottle System Application Data Sheet (Form 1676) (pdf) (opens in a new tab)

- SENSOR Sample Cooler Specifications Data Sheet (Form 1691) (pdf) (opens in a new tab)

- SENSOR Wake Frequency Calculation Data Sheet (Form 1821) (pdf) (opens in a new tab)

- SENSOR Lag Time Calculation Data Sheet (Form 1822) (pdf) (opens in a new tab)

- Subject Matter Expert Spotlight (Form 1876) (pdf) (opens in a new tab)