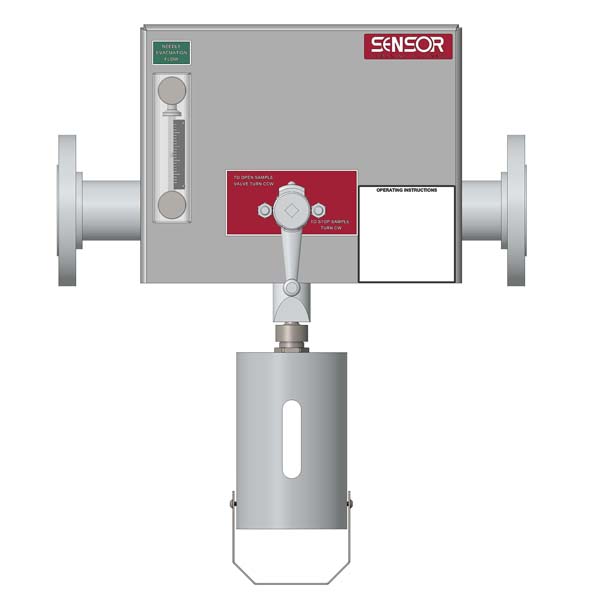

Basic Bottle Sampling Systems

Models: BBSS

Warranty: 1 Year (pdf) (opens in a new tab)

Models: BBSS

Warranty: 1 Year (pdf) (opens in a new tab)

Models: LGSS, VSS

Warranty: 1 Year (pdf) (opens in a new tab)

Models: DTSS

Ranges: Max Pressure - 1800 psig; Max Temperature - 350ºF (higher pressure and temperature ratings available)

Warranty: 1 Year (pdf) (opens in a new tab)

Models: HPSS

Warranty: 1 Year (pdf) (opens in a new tab)

Models: HFSS

Ranges: Max Pressure - 600 psig; Max Temperature - 350ºF

Warranty: 1 Year (pdf) (opens in a new tab)

Models: IVSS

Warranty: 1 Year (pdf) (opens in a new tab)

Models: PIBSS

Warranty: 1 Year (pdf) (opens in a new tab)