Data Sheet

SORinc.com

Inline Sampling Systems

Models:

ISS

Warranty:

(opens in a new tab)

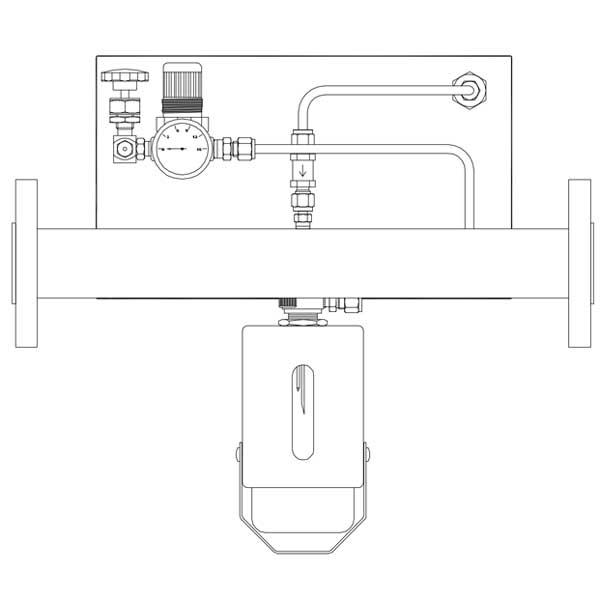

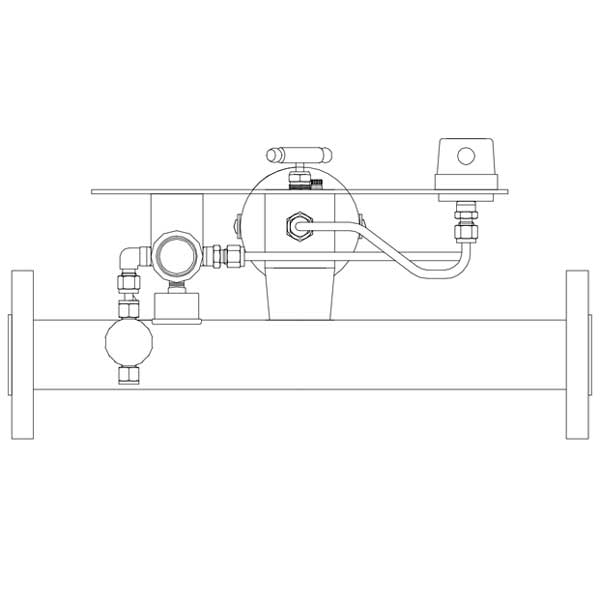

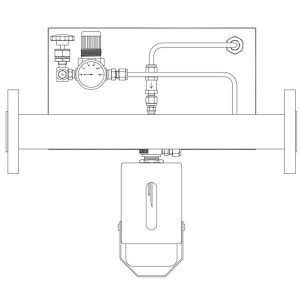

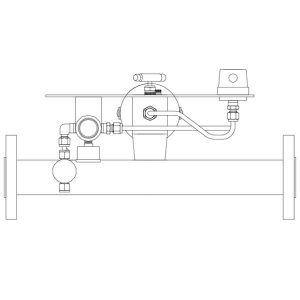

(opens in a new tab)The SENSOR Inline Grab Sampling System (ISS) fits into a piping system without the need to utilize, or create, a pressure differential fast loop to take a sample. It can be designed to fit into virtually any diameter piping system and any flange configuration. The ISS uses a special long-body needle valve and can also be configured with a collection chamber.

SENSOR welds a specially designed sample valve into a spool piece matching your piping specification. The valve body can be fully purged to ensure zero dead volume by residual elimination. This purge eliminates any potential plugging issues and ensures process media is not vapor locked in the dispense tube.

Typical applications for the SENSOR ISS include hot oil, refinery “bottoms”, and residual oil. Our robust valve is fitted with graphoil packing for high-temperature applications. We heat trace any exposed areas to maintain adequate process temperature to allow for a free flowing sample. We enclose the valve and sample receptacle in a specially designed enclosure that can be fitted with an optional educator to exhaust harmful vapors to a safe location.

- Available in a wide variety of piping materials and end connections

- Suitable for high temperature, high viscosity service

- Available with open tube “stinger” or process needle

- Can be provided in virtually any material to match the piping system in which it is installed

- Available with collection chamber, model PIISS

- Optional SENSOR Sampling CONCENTRIC single needle design is available

- Operating Instruction Manual included

Be sure and look at the other sampling system models that are available like the RAM Sampling Systems(opens in a new tab)