Sampling Systems: Flare Gas Applications(PDF)

Michael Bequette, P.E. SOR Controls Group, Inc.

Flares are used extensively where flammable gas may exist such as in industrial processes or oil & gas production facilities. For example, multiple flares can be seen at many petroleum refineries. Flares provide a mechanism to handle upset conditions in a safe manner by combusting hazardous gases. Some examples of this may be an overpressure condition such as on a pressure relief valve or rupture disk where pressures of natural gas in a line need to be reduced. Flares will provide a mechanism to remove some of the gas to help reduce the pressure in the line. Other examples include Oil & Gas production facilities where natural gas may be extracted with oil. In these situations, flaring gas may be the only alternative if the infrastructure to pipe the gas out is not in place. When flares combust the waste stream from a process, exhaust gases depending on what is in the process is given off. In many cases, this exhaust may be harmful to the population and wildlife around the plant or harmful to the environment. Over the last several decades, the government has come out with regulations to control these air pollutants that are discharged from flares and quantifying the amount of pollutants that escape is mandatory.

Hazardous Air Pollutants also known as HAPs are a serious environmental concern. HAPs are sometimes referred to as toxic air pollutants as they pose significant health risks. HAPs are toxic substances that have been associated with causing cancer, neurological, respiratory, and reproductive problems. In addition to health concerns, HAPs negatively impact the environment in many ways. Some environmental concerns include: climate change, acid rain, water supply pollution, and smog. The United States Environmental Protection Agency (EPA) currently lists 187 compounds as HAPs ((opens in a new tab)" target="_blank" rel="noopener">https://www.epa.gov/haps/initial-list-hazardous-air-pollutants-modifications(opens in a new tab)) which are generated from many different industrial processes. (EPA, What are Hazardous Air Pollutants?) Most HAPs are defined by the category of production such as mobile sources (e.g. exhaust gases from vehicles), stationary sources (e.g. refineries, power plants, and factories), and indoor sources (e.g. activities such as cleaning).

In 1990, the Clean Air Act was amended to primarily drive compliance by establishing actionable dates to achieve the reduction in the number of HAPs. As a result of these amendments, a new requirement of technology based standards was developed for major sources and certain area sources. Major sources are a stationary source that produces or has the potential to produce 10 tons per year or more or 25 tons per year or more of HAPs, whereas, an area source is a stationary source that doesn’t follow the definition of a major source. For these major sources of HAPs, the EPA has established metrics to monitor emission and determine the effectiveness of the control technology commonly referred to Maximum Achievable Control Technology or MACT standards. (EPA, Summary of the Clean Air Act) The control technology as defined in MACT standards doesn’t necessarily mean costly emission control systems such as scrubbers, and thermal oxidizers, but can be defined as processes and methods to determine and limit the quantity of HAPs. These MACT standards bound users to specific emissions parameters objectively. MACT standards are set by the EPA based on source category that has been achieved by the best-performing in that category. This level is then set as the baseline throughout the industry. The MACT standards established, developed into the National Emission Standards for Hazardous Air Pollutants (NESHAPs) specifically to safeguard against emissions of HAPs from major sources.

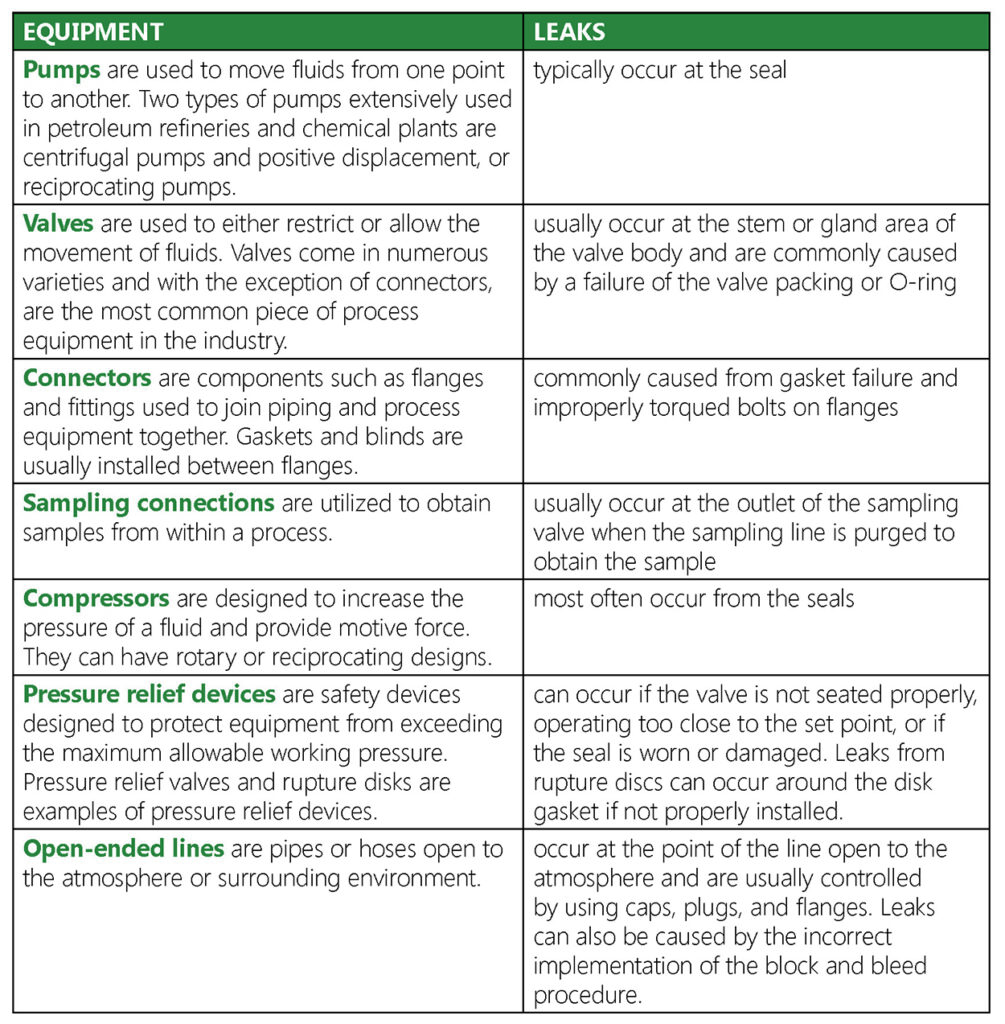

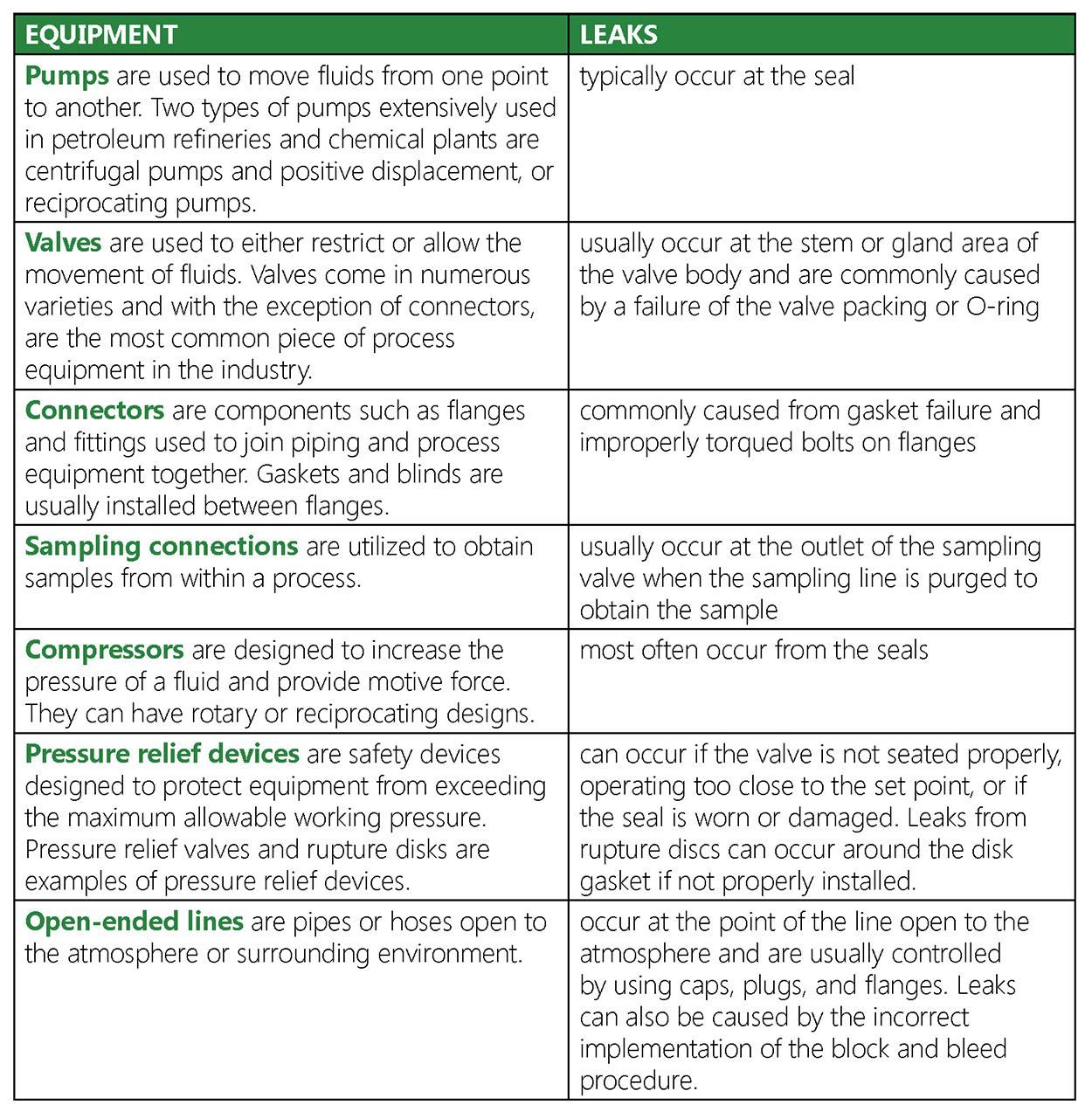

Valves, flanges, connectors, and pumps are some of the leading locations for release of HAPs and Volatile Organic Compounds (VOCs). These releases are typically the result of leaks at these components. According to the EPA’s Leak Detection and Repair a Best Practices Guide, “A typical refinery or chemical plant can emit 600-700 tons per year of VOCs from leaking equipment, such as valves, connectors, pumps, sampling connections, compressors, pressure-relief devices, and open-ended lines.” (EPA, Leak Detection and Repair A Best Practices Guide) Two methods are used to combat emissions from leaking equipment: leakless components, or Leak Detection and Repair (LDAR). LDAR is a method that reduces emissions from leaks by identifying the leak as it occurs and repairs it within regulated time frames. Table 1 defines some of the common leak sources.

Table 1 – (EPA, Leak Detection and Repair A Best Practices Guide)

To comply with these standards, quantifying the amount of pollutants being released is required. In order to properly, and safely measure the pollutants, a sample of the waste should be taken. Automatic sampling systems provide a safe and environmentally friendly way to extract the needed sample. Sampling systems can be a source of leaks and should comply with LDAR. Sampling systems come in many different styles and configurations, as no two sampling systems are exactly alike. Sampling systems can take a process sample with operator interaction or automatically without any operator interaction. Manual operation allows for surveillance of the process at random times. Further, manual operation allows for repeated samples to account and correct for special circumstances that may have inappropriately influenced the sample that was not representative of the source. Automatic sampling without operator interaction can look at events such as a non-standard flare event to quantify pollutants such as NOX and SO2 or some other waste stream chemical. The advantage of this convenience allows scheduling samples in terms of timed samples or events. In addition, it meets the regulatory requirements of 40 CFR 50.4 in terms of regular timed samples for SO2 sampling in a defined periodic time period. Appendix A of these federal regulations define the acceptable sample probe, absorber, moisture trap, flow control and measurement, particulate filters, temperature control, vacuum pump requirements, and sample bottle so that the sampling system and procedures doesn’t interact with and invalidate the sample. A sampling system has 6 overall functions:

- To take a representative sample that is based upon the specific needs of the application.

- Condition and treat a sample so that it can be used with an analyzer. This may include removing solids, moisture, or temperature control.

- Switching sample streams to get multiple reference samples of a process.

- To handle caustic, hazardous, and extreme environmental conditions that could adversely impact the operator or environment when attempting to extract the sample.

- To allow transport of the sample for analysis.

- To allow for a mechanism to dispose of the sample.

Sampling systems typically are of a time-based, flow-based, or volume-based scheme with samples triggered off of events associated with these schemes. These schemes can be single action or a combination of events.

- Time-based sampling will attempt to fill a cylinder over a pre-determined amount of time, although the sample period within time-based sampling can vary. Time-based sampling systems are usually used when there is a continuous flow rate or the material composition is thought to be constant.

- Flow-based sampling is designed to take samples in proportion to the flow rate. These systems have sample rates that are dependent on the flow rate and may increase or decrease in relation to this unlike time-based systems.

- Event-based sampling systems take samples when a specific event triggers the operation such as an overpressure condition, changes in density, opacity or some other monitored variable.

Many may argue, why not use a continuous analyzer to accomplish this? Well flares are typically used to handle upset conditions. Therefore, in normal conditions the flowrates, pressures or caustic concentrations may be small compared to an upset condition where flowrates, pressures, etc. are very high. Being able to provide a mechanism to analyze this continuously is very costly and technically challenging. Most analyzers can’t be calibrated to handle the high flow conditions, but also operate at the very low range and stay in calibration. This dynamic range condition challenges many instrument companies. Grab sampling systems correct these problems. However, many grab sampling systems on the market do not comply correctly with MACT, LDAR and NESHAP standards. These systems in the past were constructed with an open tap (two way valve) or Strahman type. This effectively provided no vent capture or fast loop to prevent operators from taking a bad sample or exposing the sample to the environment. Effective sampling systems providing compliance to MACT, LDAR, and NESHAP are closed loop with a closed vent. There are best practices to help accomplish this such as:

- Ensuring there is no condensation or other items that can interfere with the sample.

- Understanding material compatibility to the process stream so that the system is inert to the process.

- Ensuring an adequate purge system to remove residual sample material from the system.

- Understanding remote location of how sampling ties into the process.

- Location placement in the process line to get a true representative sample.

- Filtering to separate liquid mixtures.

- Sample lines should be as short as possible.

- Look to prevent pressure drops across valves and fittings.

- Design to use as few fittings as possible to prevent potential leak points or weld fittings as needed.

Sampling systems are a designed and engineered product at the time of order. Sampling systems can be very complicated if one considers how to get a true representation of a sample from a process. If not carefully considered depending on the application, phase changes may occur, or if not treating the process correctly, damage to expensive analyzers could result. If samples are not truly representative, inaccuracies will occur, causing many serious ramifications such as increased environmental pollution, as well as costs to the end-user. Handling the sample can be a potential point of contamination. Some common errors associated with sampling systems in terms of handling are:

- Opening the valve on the cylinder to determine if the cylinder is still under vacuum.

- Opening the valve on the cylinder to verify whether if there is a sample in the cylinder.

Contamination can also occur through the selection of valves, and other parts of the system. Some components may not be designed for use with vacuum and result in leakage that brings outside air in. This could also provide false readings during analysis.

Many sampling systems have similar components that are used, but they have to meet the necessary design parameters of the system they expect to extract samples from. Designs require process information such as pressure, flow rate, temperature, viscosity, vapor pressure, material compatibility, and sample size. In addition, placement of the sampling system and its interface into the process has tremendous variability. Some systems may require gas coolers or heaters to maintain a true representation of the sample.

CASE STUDY

Background

A major United States Oil & Gas Refinery needed an effective solution to measure flare stack emissions and safely transport a sample to a laboratory for analysis. Initially, continuous on-line analyzers were investigated but the refinery concluded that the continuous analyzers were significantly more expensive, required more in terms of installation, had limited range ability, and continual maintenance added additional costs.

Solution

The end user selected a sampling system that was more effective in terms of cost, reliability, and representation of the sample due to the dynamic nature of the application. The basic sampling system design consisted of using sample cylinders that are sequenced through time of the flare event to give an effective representation of the sample needed for analysis. Figure 1 shows an image of the actual system.

A Piping and Instrument Diagram (P&ID) for the system is shown in Figure 2. The sampling system proposed has a maximum design pressure of 60psig and a maximum design temperature of 350 degrees F. This system has an integrated Allen Bradley PLC to control the opening and closing of solenoids, provide status of the system, initiate sampling, and provide alarming to the plant DCS.

For overpressure protection, several rupture discs were used in the system with check valves ensuring proper flow direction. The sampling lines from the flare stack were ½” stainless steel tubing and run through a gas liquid separator that is filtered with an automatic drain. The samples go through a heat-resistant diaphragm pump to a 500 CC sample cylinder. Pressure switches are also used as an input into the PLC to detect high pressure fault conditions.

Gas sample systems can be simple or highly complex systems depending on the nature of the application required for sampling. Sampling systems can be a crucial piece of equipment to prove compliance to regulations but also to properly managing a process. In order to have accurate, reliable, and repeatable gas analysis, a well-designed sampling system is necessary to ensure the sample is not contaminated. In addition, techniques for proper sampling are significant in determining the quality and value of the gas being sampled. Obtaining a proper high quality sample that is representative of the process can be extremely challenging, but necessary to truly understand what the process may contain.

References

EPA. Leak Detection and Repair A Best Practices Guide. n.d. 28 July 2016 <https://www.epa.gov/sites/production/files/2014-02/documents/ldarguide.pdf>.

—. Review of the Parameters for Properly Designed and Operated Flares. 1 May 2012. 26 July 2016 <https://www.epa.gov/sites/production/files/2016-06/documents/2012flarechargestatement.pdf>.

—. Summary of the Clean Air Act. n.d. 21 July 2016 <https://www.epa.gov/laws-regulations/summary-clean-air-act>.

—. What are Hazardous Air Pollutants? n.d. 21 July 2016 <https://www.epa.gov/haps/what-are-hazardous-air-pollutants>.

For more information, please contact:

Michael Bequette, P.E. – VP of Engineering SOR, Inc.

Michael Bequette has dual undergraduate degrees in Electrical Engineering, and Theoretical Physics from Kansas State University. He has a Master Degree in Electrical Engineering from the University of Kansas, and a Master of Business Administration from Park University. Michael has 23 years of experience in the oil and gas space, as well as aerospace, glass, pulp and paper, and water/wastewater. Michael is a licensed professional engineer in multiple states, holds 4 patents for fiber optic product development and capacitive fault location and is a senior member of IEEE.