Product Selector

Enter your information below to find the right SOR Controls Group product for your needs.

1100 Series Magnetic Level Indicators

Models: 1110, 1120, 1130

Ranges: Made to order

131 & 141 Nuclear Qualified Differential Pressure Switch

Models: 131/141

Warranty: 1 Year (pdf) (opens in a new tab)

1400 Series Temperature Sensor Assemblies

Models: 1440, 1443, 1445, 1450, 1455

Warranty: 1 Year (pdf) (opens in a new tab)

1510 Side Mounted Level Switch

Models: 1510

Ranges: vac to 5000 psi, vac to 345 bar; -40° to 400°F, -40° to 204°C

Certifications: Unit: ATEX, CSA (US and Canada), INMETRO, SIL, UKCA, IECEx

Warranty: 5 Years (pdf) (opens in a new tab)

1520 Electric Flow Switch

Models: 1520

Ranges: vac to 5000 psi, vac to 345 bar; -40 to 400°F, -40 to 204°C

Certifications: Unit: ATEX, CRN, CSA, INMETRO, SINGLE SEAL, SIL, UKCA, IECEx

Warranty: 5 Years (pdf) (opens in a new tab)

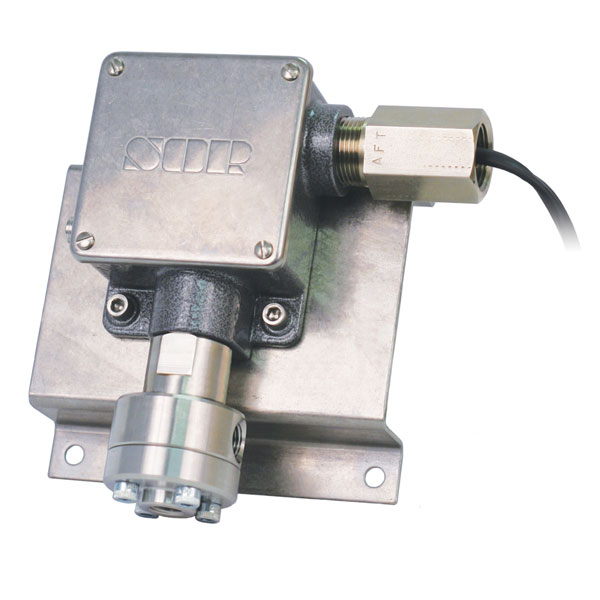

1530 Pneumatic Level Switch

Models: 1530

Ranges: vac to 5000 psi, vac to 345 bar; -40° to 400°F, -40° to 204°C

Warranty: 5 Years (pdf) (opens in a new tab)

1540 Side Mounted – Non-Bleed Pneumatic Level Switch

Models: 1540

Ranges: vac to 1500 psi, vac to 100 bar; -40° to 400°F, -40° to 204°C Maximum process pressure 60 SCFH (1.7 CMH)

Warranty: 5 Years (pdf) (opens in a new tab)

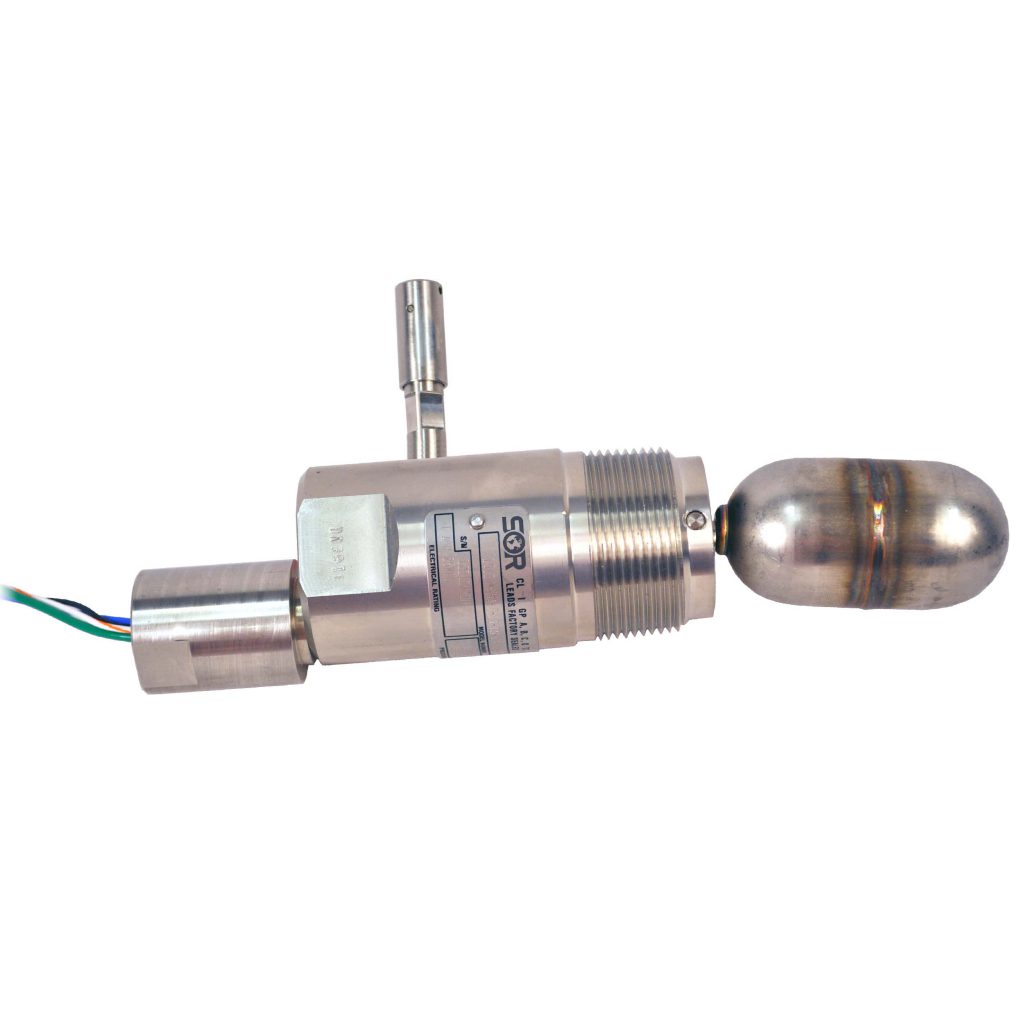

1550 Top Mounted Level Switch

Models: 1550

Ranges: vac to 473 psi, vac to 32.6 bar; -40° - 400°F, -40° - 204°C

Certifications: Unit: ATEX, CSA (US and Canada), INMETRO, SIL, UKCA, IECEx

Warranty: 3 Years (pdf) (opens in a new tab)

1710 Compact Level Switch

Models: 1710

Ranges: vac to 1799 psi (124 bar) -40° to 700°F (371°C)

Certifications: Unit: ATEX, CSA (US and Canada), IEC, KOSHA, SIL

Warranty: 5 Years (pdf) (opens in a new tab)