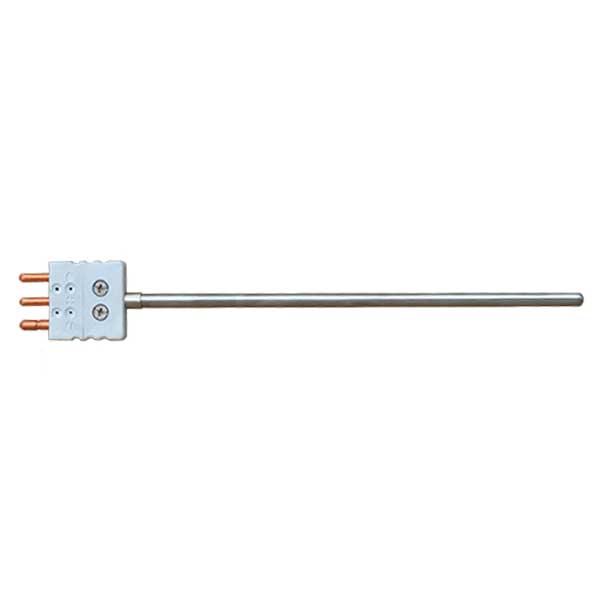

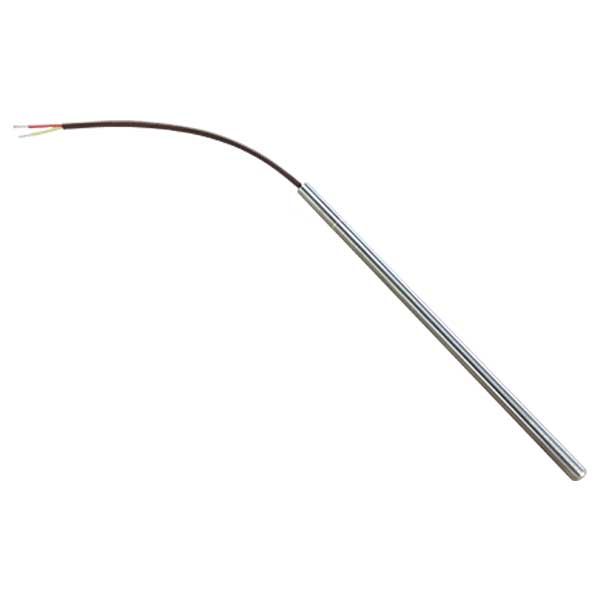

Field Adjustable RTD Sensor Element

Models: Various

Warranty: 1 Year (pdf) (opens in a new tab)

Models: Various

Warranty: 1 Year (pdf) (opens in a new tab)

Models: Various

Warranty: 1 Year (pdf) (opens in a new tab)

Models: 1150

Warranty: 1 Year (pdf) (opens in a new tab)

Models: 1250

Warranty: 1 Year (pdf) (opens in a new tab)

A resistance temperature detector (RTD) operates on the principle that a change in the temperature of a metal causes a corresponding change in that metal’s electrical resistance. The resistance of the RTD increases as the temperature rises. SOR can provide a replacement for any failed thermocouple, RTD, or temperature assembly.

In most process applications, the temperature sensor is inserted into a thermowell or protection tube. This protects the sensor from its environment and facilitates easy maintenance. These assemblies generally consist of a head, nipple-union-nipple, and thermowell.

Factory-Tested

Multiple Design Options

Tiers of Accuracy for Different Applications

Large Temperature Range Capabilities