Sight Glass or MLI, What Costs More over 5 Years?

Local level indication is an important measurement for many process control applications. Not only does it provide a reliable way to confirm the level height, but it also allows a way to check/calibrate level transmitters, temporarily manually control the liquid level when the normal control systems are down, and offers a redundant technology to measure level. The two main technologies used for local indication are armored sight glass and Magnetic Level Indicators (MLI).

Local level indication is an important measurement for many process control applications. Not only does it provide a reliable way to confirm the level height, but it also allows a way to check/calibrate level transmitters, temporarily manually control the liquid level when the normal control systems are down, and offers a redundant technology to measure level. The two main technologies used for local indication are armored sight glass and Magnetic Level Indicators (MLI).

Armored sight glass usually consists of two armored castings that sandwich a piece of glass allowing direct visibility of the liquid level. A Magnetic Level Indicator is typically made up of a float containing a magnet that follows the liquid level inside of a chamber. The position of the float inside the chamber is indicated outside by dual-colored flappers embedded with magnets. As the magnet inside the float interacts with the magnets on the flapper outside of the chamber, the flapper turns and changes color to indicate level.

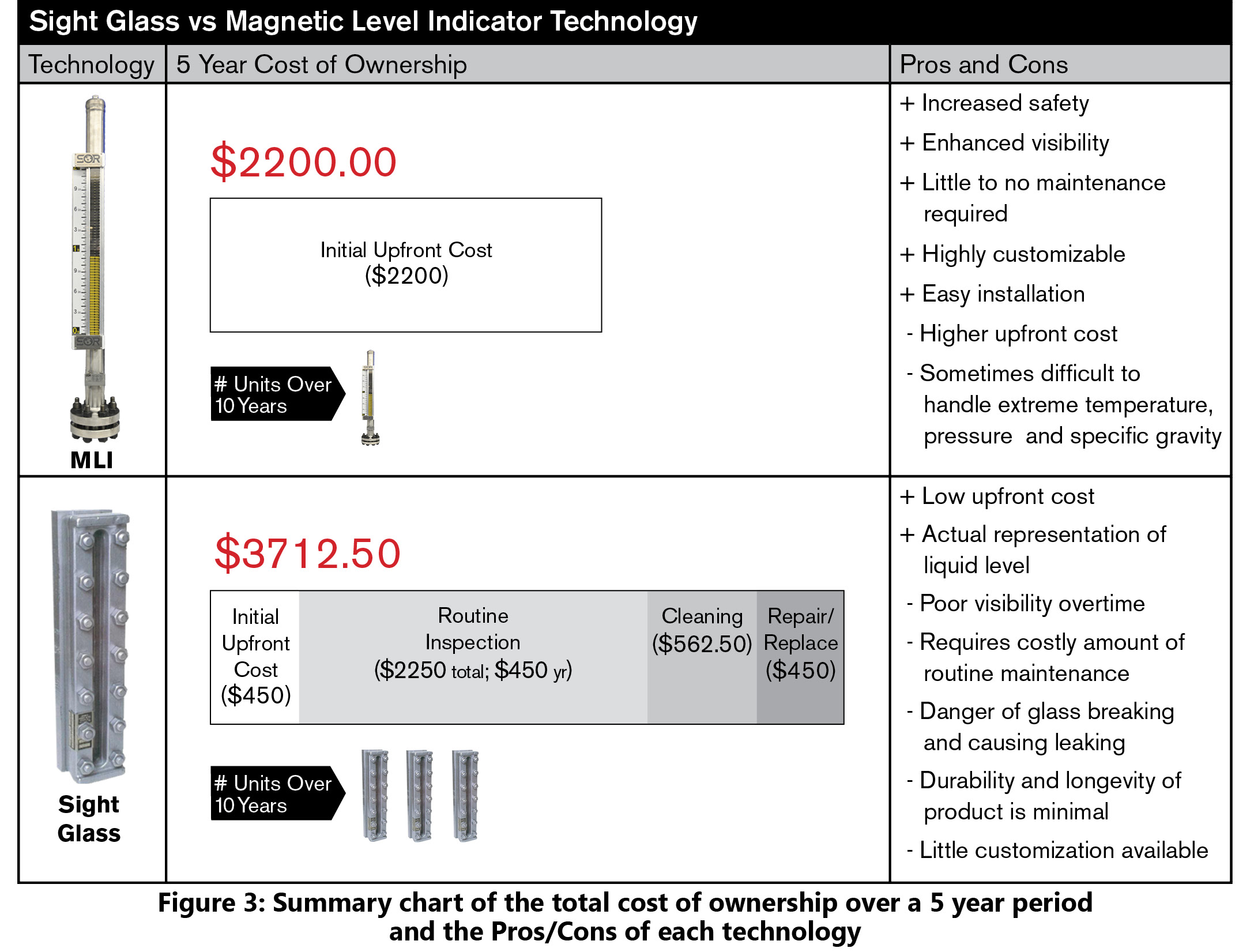

When deciding which technology to use, it is important to look at the long term cost of ownership rather than just the upfront cost of the unit. Sight glass technology typically has a much lower upfront cost than a MLI, however a MLI has many benefits during installation and normal operations that results in a much lower total cost of ownership in the long run.

The 4 key ways a MLI will actually reduce overall cost over time and improve functionality vs. sight glass are below. We will go through an example of comparing the total cost of ownership of a sight glass vs. an MLI over a 5 year period. A lot of these values are estimates and will vary greatly on changing applications and from plant to plant. In this example we will use a 3 ft indication length and assume our initial upfront cost of the sight glass is $450, while our MLI has a starting cost of $2200.

- Enhanced Safety

- Maintenance

- Increased Visibility

- Easier initial installation and addition of transmitters and switches

1. Enhanced Safety

Sight glass has many shortcomings when it comes to safety. Because it uses glass as one of its pressure containment walls, the risk of breaking dramatically increases when dealing with high temperatures, pressures, and corrosive materials, all scenarios where in the event of failure of the sight glass, extreme harm to the environment and/or an operator can occur. Temperature and pressure cycling will cause fatigue overtime on the glass and sealant material resulting in the possibility of cracking and leaking to occur. Corrosive chemicals can also attack the glass and sealant material resulting in a similar outcome.

Due to its heavy-duty construction of welded stainless steel pipe, MLI’s offer a solution that is almost unaffected by long term effects of cycling of pressure and temperatures as well as corrosive process materials. The cost of a sight glass breaking is not really quantifiable; however it can be guaranteed that it will be more expensive than initially using an MLI, especially if someone is hurt in the incident. Eliminating this safety risk is a huge advantage alone for the MLI.

2. Minimized Maintenance

The maintenance of sight glass is the greatest fixed cost adder over a 5 year period. When it comes to maintenance, there are 3 parts here: Routine Inspection, Cleaning, and Repair/Replacement.

Routine Inspection

Time between sight glass inspections will vary per the end users operations procedures, however typically plants have a routine procedure to inspect every sight glass once a month. This involves isolating the sight glass, draining the gauge, and taking a flashlight to inspect the glass for any distinct reflections that could represent a scratch or crack in the glass. This typically takes about 30 min depending on the size of the sight glass. Roughly saying the cost of doing this procedure is $75/hr, depending on if the plant requires two people to always be together while doing this and varying salaries. This would result in about $450/ year alone on inspections of one sight glass.

Cleaning

Anyone who has ever used or seen a sight glass in service knows that overtime the glass become cloudy and dirty, making it nearly impossible to read the level. Most plants have routine cleaning schedules, however because of the very time consuming process of cleaning a sight glass, some end users only do a cleaning once the liquid level is no longer visible. For the purpose of this example, assume that the average sight glass will need to be cleaned once every two years on average.

This is a very time consuming task, and will typically take between 2-3 hours to complete depending on the size of the glass. Using the same $75/hr, this results in another $225 every 2 years. Comparing this to the MLI, routine cleaning is not needed as the indicator is external to the process.

Repair/Replacement

With sight glass, there are many components that can fail or cause leaking. The main failure points however are going to be the glass itself and/or the sealing gasket. Overtime, it is inevitable that one of these components will fail due to fatigue. This would warrant repairing or replacing the sight glass all together.

Replacement parts are cheap, only $20 to $30, however it is a very time consuming process to repair these items. Typically, end users will determine that it will actually cost less to just buy a new section rather than repair the old unit.

Magnetic Level Indicators carry very long warranties, typically 5 years as opposed to the standard 1 year warranty on a sight glass. With that as well, MLI’s will have a much longer life expectancy past their warranty period, typically lasting 10+ years without any repair or replacement. Sight glass will normally last from 3 to 5 years without needing any repairs or replacements. After a 5 year period, that is another $450 for a replacement sight glass.

3. Increased Visibility

Increased visibility ties into safety. A lot of times the glass on a sight glass is so cloudy that operators will have to get their face very close to the glass to be able to determine the level. If there is any leak in the glass, that operator could be  exposing themselves to the hazardous fumes/process.

exposing themselves to the hazardous fumes/process.

Comparing this to a MLI, some models can be seen from over 250 ft away and have a 200° viewing angle. Since the indicator portion is external to the process, it will never become cloudy or unreadable like a sight glass will.

4. Easier initial installation and addition of transmitters and switches

Installation time is greatly reduced for an MLI over a sight glass as an MLI can be made to match up directly to existing piping connections. Typical installation consists of simply connecting the two process connections to the vessel.

For sight glass, they are typically only available in 12” sections due to the glass’s weakness. They then need to be stacked during assembly by either welding each section together or threading them in. This creates more potential leak paths and takes a lot longer time to set up initially.

In addition to ease of installation, transmitters and switches can be easily added to the MLI chamber whereas a sight glass does not have capability to customize the chamber to function as a measurement bridle.

Summary of cost over a 5 year period

Sight Glass

- Initial upfront cost = $450

- Routine Inspection = $2250 total ($450/year)

- Cleaning =$562.5 total ($225/2 years)

- Repair/Replacement = $450

Total cost of Sight glass over 5 year period = $3712.50

Magnetic Level Indicator

The total Magnetic Level Indicator cost over a 5 year period is only the initial upfront cost of around $2,200.

The result over a 5 year period is a cost savings of nearly 70% if one were to use an MLI over a sight glass. This cost savings is only the fixed costs associated with an MLI and sight glass, and still does not take into account the added safety and ease of use operators get when using an MLI over a sight glass. There are some applications with low pressure, low temperature, and nonhazardous material where sight glass may be the best thing to use, however typically a MLI will cost less in the long run.

Author Bio:

Name – Matt Gasparovich

Title – Product Manager

SOR Inc.

14685 W 105th Street P.O. Box 15964

Lenexa Kansas 66215

913-988-2630

www.sorinc.com