Data Sheet

SORinc.com

SENSOR CONCENTRIC Needle System

Models:

CONCENTRIC

Ranges:

Sizes: .065”/.109”, .083”/.148” and .109”/.203”

Warranty:

(opens in a new tab)

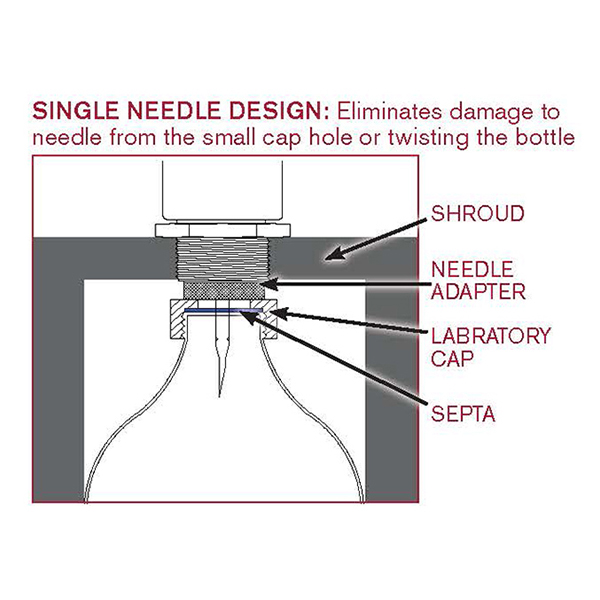

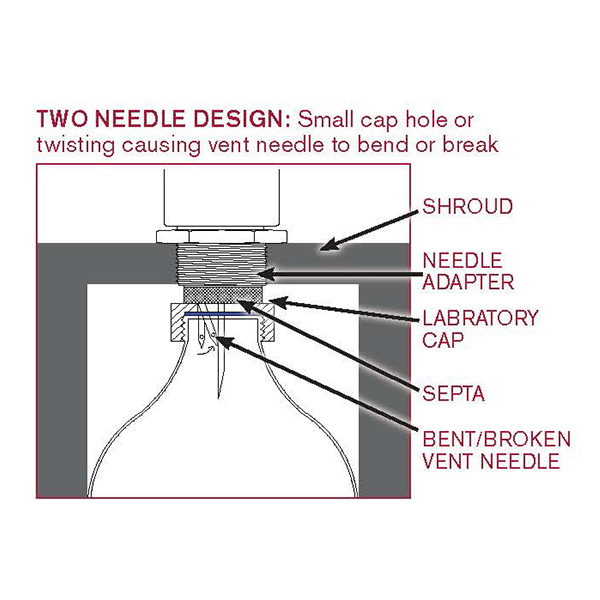

(opens in a new tab)The CONCENTRIC Needle design combines the function of the 2-needle or dual system in one concentric combination of two different-sized needles, one within the other. Process travels through the inner needle into the bottle and the displaced air and vapors from the bottle are vented back through the annulus between the two needles and plumbed to a safe area. The process vent is available in three sizes: .065”/.109”, .083”/.148”, and .109”/.203”.

When samples are collected from a chemical or refining process, capturing the VENT and moving it away from personnel is one of the most important safety functions of the system. Many of these chemicals are hazardous to operations personnel, which makes grab sampling a potentially hazardous task. Standard bottle systems from SENSOR utilize a process needle for filling the bottle and a separate needle for venting it. The needles, in combination with a bottle, cap, and membrane septum, provide for the “closed-loop” nature of the sample system.

- Aligns the process and venting functions with the center of the sample bottle

- Can be ordered as an OPTION without changing the Sample Station design

- Can be supplied in the same materials as the dual needle system

- Can improve the reliability of the sample station in the field, if utilized for the right applications

- Can be used with vials with crimp-on caps

- Can be used for small sample bottles (less than 1 ounce)